Every Dingwall is an intricate universe of vision and craftsmanship, with each instrument element expertly designed to work in perfect balance. From creating the first-ever long-scale bass strings to designing bridges that allow vibration and frequencies to interact with the whole instrument in the most musical way possible, Dingwall Guitars builds every bass with passion and reverence.

Have you ever wondered how we created and designed our iconic custom pickups? This issue of the Dingwall Guitars newsletter features that story, and it’s a story I bet lots of people can relate to.

Thank you for being a part of the Dingwall Guitars family. Read on to enjoy insider Dingwall stories, and the latest updates to get in touch with us via email, Facebook, or Instagram. We love hearing from you.

Sheldon Dingwall

Taking risks and leaps of faith have been a consistent part of Dingwall’s history and an essential part of our creative process.

The journey started with the FD1. We were having supply issues and one of my early mentors – Glenn McDougall from Fury Guitars – recommended that we start making our own pickups, which would give us better control over both the design and supply.

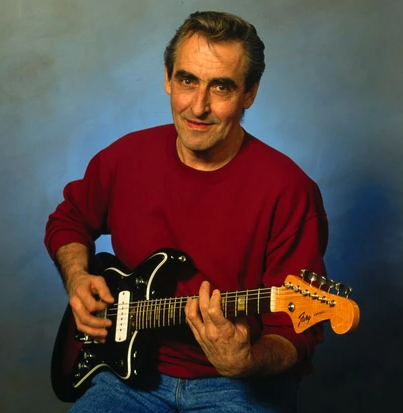

Glenn McDougall from Fury Guitars

Glenn helped with the initial design and then wound prototypes for us until we arrived at the final FD1 spec. We built a small vacuum-forming machine and taught ourselves to vacuum-form plastic sheets into raw shells, which we CNC engraved with our logo. Once the pickups were assembled and epoxy potted in the shells, we drilled and counterbored them for mounting screws and bead-blasted them for texture.

The tone of the FD1 pickup was very clean and HiFi sounding, with an aggressive spike at about 1.2 kHz. We added a passive mid-circuit and tuned the circuit to sweeten up the 1.2 kHz range.

We called the passive mid circuit the bluEQube partially because we used blue epoxy for potting the circuit and ice cube trays as a mould to hold the epoxy. The circuits looked like blue ice cubes with two wires sticking out. I liked the way the two words lined up with E and Q capitalized. Sometimes names just work out.

coil winding machine.

With the bluEQube circuit engaged the tone sat back in the mix. Switching out the circuit gave you a slight bump in output and a more aggressive and cutting tone.

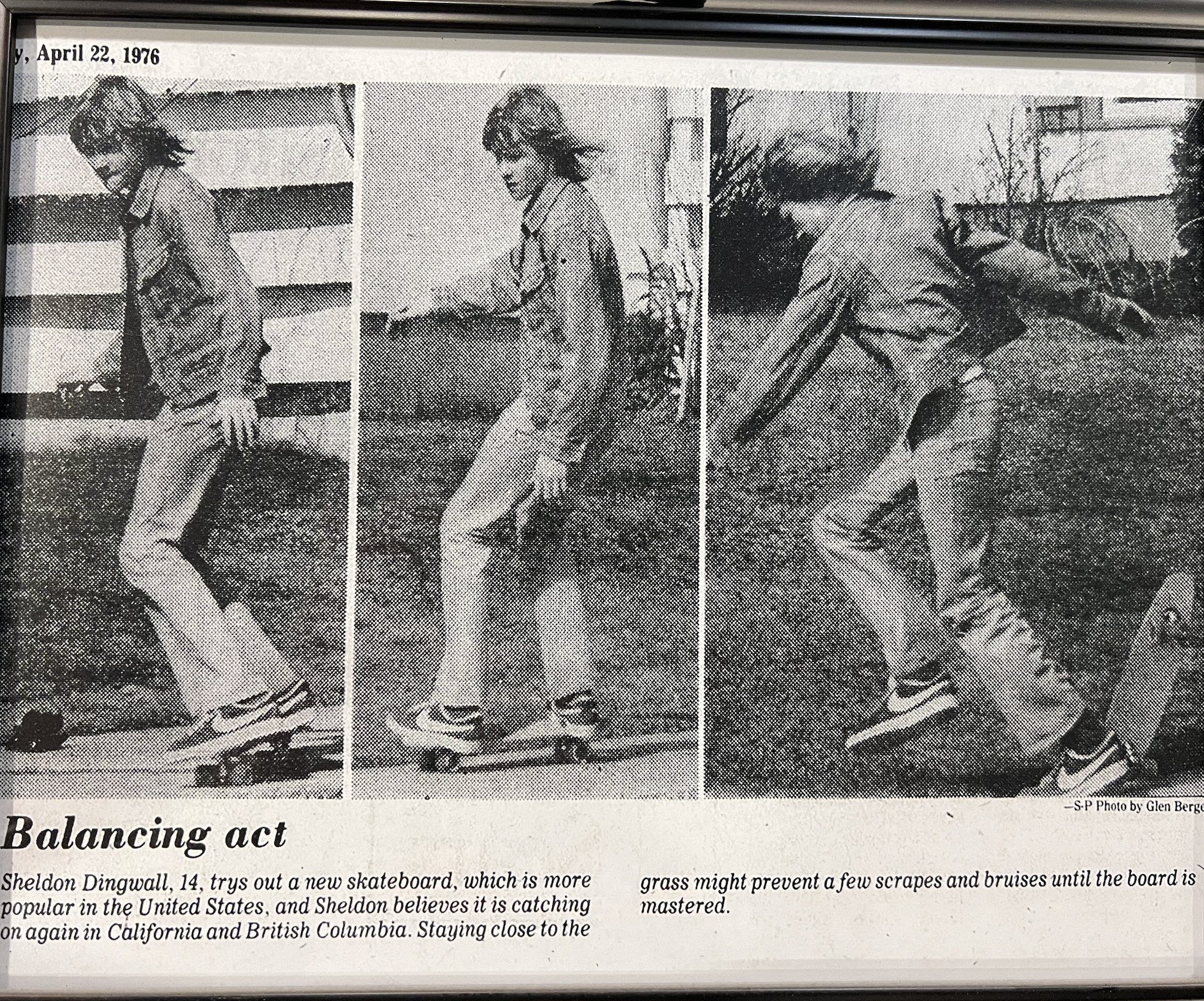

The fire that levelled the Dingwall shop in 1996 didn’t leave me with much in the way of things I could sell to raise funds to invest in pickup manufacturing. However, some of my 70’s skateboard gear survived and was quite collectable by the time the late 90s rolled around.

I put everything up on eBay and managed to generate enough cash to purchase a very used coil-winding machine. Next, we had to figure out how to design and fabricate custom aluminum fixtures and supports to turn the coil winder into a pickup winder. Once we figured out that part, we programmed the winder with Glenn’s FD1 specs to test the new machine.

Sheldon Dingwall, 14, tries out a new skateboard

The resulting pickups sounded nothing like Glenn’s. They had a huge bottom-end, and the aggressive mid-spike was gone. These became the short-lived FD2.9. Soon to follow was the FD3 – a pickup model that has been in continuous production for over 20 years. Today, we have 6 Dingwall pickup models and are constantly working on new designs to increase the performance and musicality of Dingwall basses.

People thought we were crazy to try to make our own pickups. At the time, the popular perception of in-house pickups was that they were of lower quality and performance than pickups sourced from external specialists. It was a huge risk, but I believed that it would allow us to further advance the tone of our basses. Designing and making our own pickups was a leap of faith on many levels, but I truly believe the freedom to evolve our tone has been worth the effort.

We’d love to hear how Dingwall Guitars has inspired your practice and performance!

Davis Baker takes us behind the scenes at Dingwall Guitars to see how our custom pickups are made.